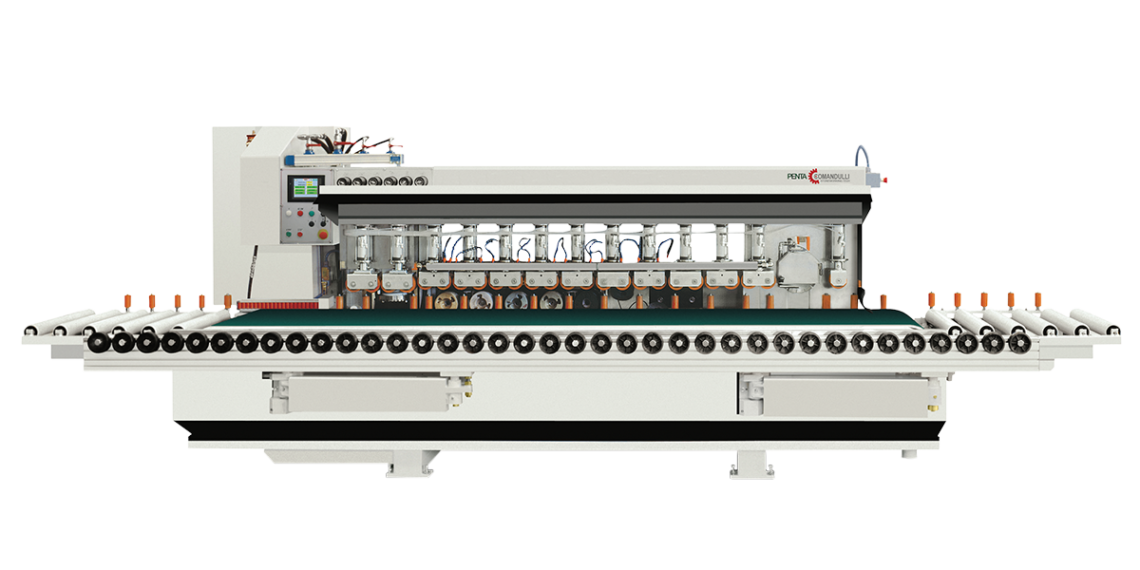

Penta

Small in size, but powerfull in performance

features

technical data

workings

Automatic edge poliscing machine able to perform all the finiscing operations on marble and granite slabs used in the building field, furnishings and monuments.

It performs gauging, straight edge, bevels, lower and upper groove through fast and simple procedures.

01. features

The exclusive features of a Comandulli machine Penta

- Steel structure, electrowelded, fully worked by milling machine.

- All our machines are protected against corrosion through a modern treatment

that follows different phases: sandblasting, metallization and painting The painted covers are subject to cataphoresis treatment, cartes in stainless steel. - Converyor belt leaning on a stainless steel plate, driven by specific grooves.

- Slab locking by pneumatic pistons.

- Floating edge polishing unit.

- Electrical spindle working.

- Possibility of performing straght edges on slabs with different thickness ang shape st the same time.

- Possibility of partial workings.

- Water collection tank.

- Colour touch screen.

- Possibility to set the belt speed from control panel.

- Laser to detect the position of the pieces on the belt and their length.

Equipments

- Gauging/calibrator tilting to 90°.

- Floating spindles for the edge (n. 5).

- Spindles for the bevels (n. 4)

- Spindle for lower / upper groove tilting to 45°.

- Extendible bar to support bigger pieces.

- Rollers for material loading/unloading.

Options

- Possibility to make partial workings with the drip unit (vertcal axis motorised and visualised on the screen)

- Possibility to polish narrow pieces (5 cm width) and samples (splash backs of 150 mm).

- NEW DYNAMIC/SMART BELT SPEED FUNCTION: machine equipped with special software that, during the automatic cycle, varies automatically the belt speed to reduce donwtimes according to the kind working and the tools to be utilised.

02. technical data

| DESCRIPTION | PENTA 5+4 | |

|---|---|---|

| Frontal spindles | n° | 5 |

| Bevelling spindles | n° | 4 |

| Diameter of the gauging wheel | mm | 190 |

| Diameter of the polishing wheel | mm | 130 |

| Diameter of the disc for upper/lower grooves | mm | 260 |

| Advancing/feed speed (conveyor belt) | m/1' | 0 - 3 |

| Conveyor belt width | mm | 600 |

| Working thickness | mm | 6 - 60 |

| Minimum working width | mm | 80 |

| Loading plane height | mm | 750 |

| Rated output | kW | 20 |

| Dimensions (rollers excluded) | m | 3,8 x 1,7 x 1,8 |

| Weight | kg | 2800 |

03. workings

A constant challenge

When our engineers and technicians compete with each other they outdo themselves, and you are the winners. By developing superior machines, able to process various working processes at the highest quality level, we help you to satisfy the many different requirements of your customers and satisfy your creativity, by giving you the possibility to extend your business.